Pure-Cut® vs. Cryogenic Cutting Solutions in CNC Machining

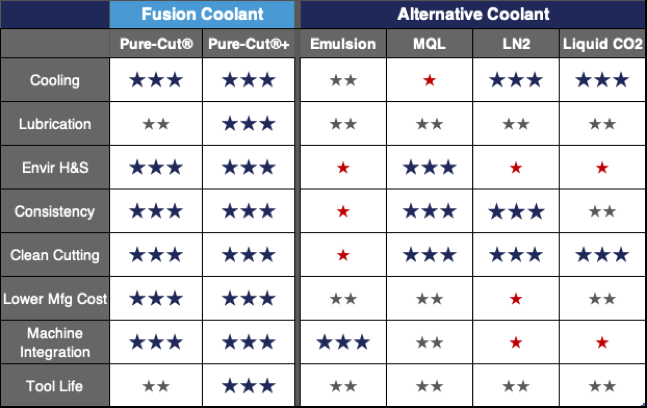

In the world of CNC machining, the choice of cooling and lubrication technologies plays a crucial role in determining the efficiency, safety, and envi...

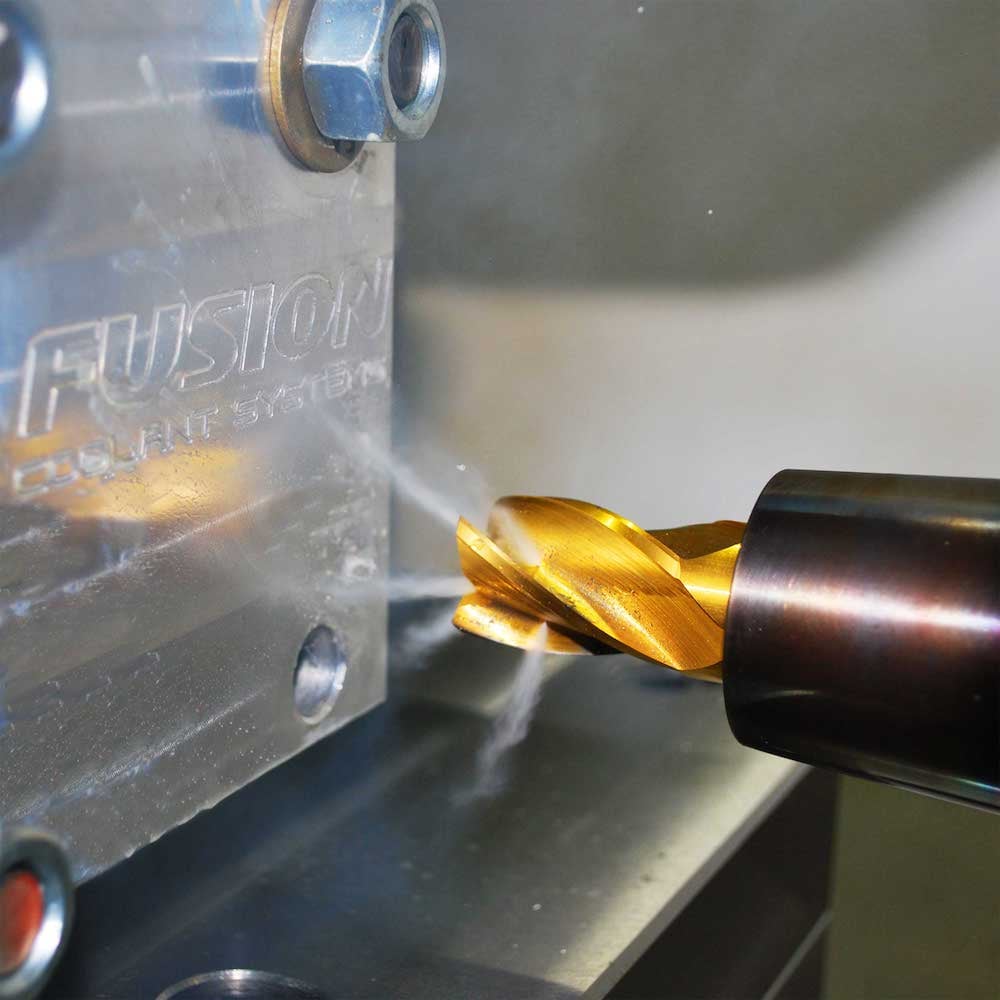

Pure-Cut® and Pure-Cut®+ bring a sustainable, advanced cooling and lubrication system to machine tools. Using supercritical carbon dioxide (CO2), the technology lowers your overall carbon footprint and increases performance.

Pure-Cut® and Pure-Cut®+ systems bring supercritical carbon dioxide technology to machine tooling with little or no oil – allowing you to achieve incredible tool life and performance improvements, and massive health, safety, and environmental benefits.

Lower your carbon footprint and create a safer work environment.

Pure-Cut uses additive-free, CO2 in its supercritical state for dry machining and is ideal for the medical industry and other applications where 100% clean environments and precise surfaces are vital. CO2, by itself, delivers similar performance results to traditional flood coolants, with the added bonus of 100% clean, dry machining.

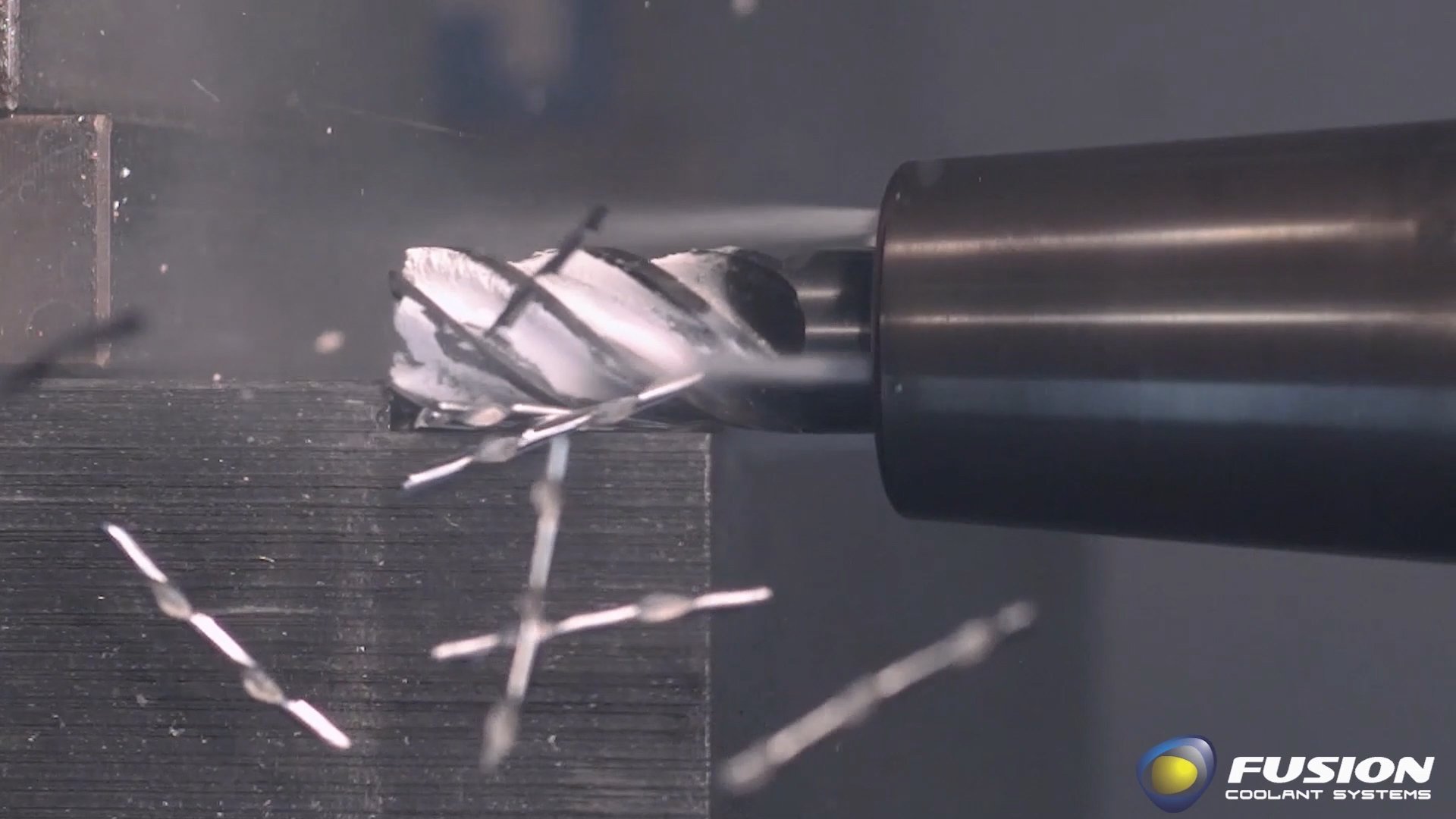

Massive speed improvements compared to traditional cutting fluids and cryogenics.

Superb surface finish when micron-level differences matter

Tools last significantly longer than with traditional lubricant in most materials.

Lower carbon footprint and eliminate worker exposure to fluid chemicals.

Easy to integrate into current machine tools. Easy to revert to traditional cutting fluids, if desired.

Efficient operation and decreased maintenance.

Fusion Coolant Systems partners with leading, global gas suppliers for seamless infrastructure and installation. Infrastructure packs can be set up for as little as one, or 1000 Pure-Cut systems in a manner that minimizes cost to you.

Use Pure-Cut infrastructure to harness supercritical CO2 as a metalworking fluid.

Cutting tools ultimately last significantly longer with most materials than with traditional cutting fluids.

Quick, consistent, clean cooling and lubrication solutions that result in longer tool life, shorter cycle time, and precise surface finishes as a competitive advantage.

Eliminate machining-induced risks of dermatitis, hypersensitivity pneumonitis, various cancers, and many other health problems.

In the world of CNC machining, the choice of cooling and lubrication technologies plays a crucial role in determining the efficiency, safety, and envi...

CNC machining is a dynamic realm where speed, precision, and efficiency converge. However, engineers often face significant challenges, including exce...

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.